1 / 3

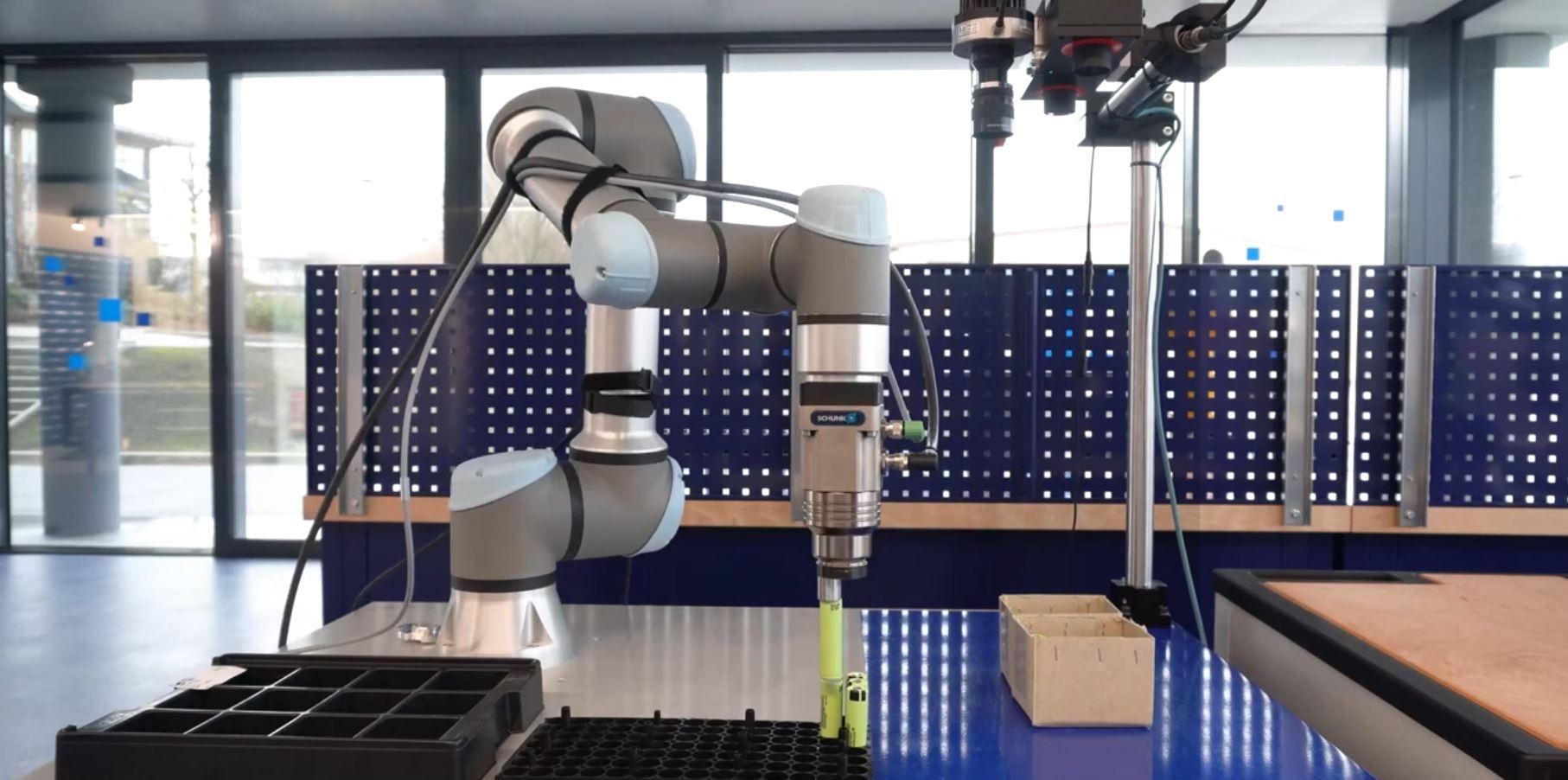

1 / 3Camera-based component separation with 2D camera system and vibration plate

Hardware Price:

Modular and flexible

ROI

in a few months

easy to

integrate

This video highlights a customer test conducted in the igus Customer Testing Area (CTA), where metal parts are isolated using a Varioshaker. Subsequently, the contours of the parts are teched into an ifm 2D camera for precise detection and analysis.

Key Points of the Video Description:

Varioshaker: A device that separates metal parts through vibratory movements for further processing.

ifm 2D Camera: A high-resolution camera used to capture and analyze the contours of the metal parts.

Objective of the Test: The test demonstrates the efficiency of the Varioshaker in isolating individual parts and the capability of the ifm 2D camera to identify these parts for quality control or automated processes.

The video impressively showcases how modern technologies are applied in automation technology to optimize processes and ensure product quality.

3 Components