1 / 6

1 / 6Robolink & Injection Molding Machine

Hardware Price:

ROI

3

months

DOF

5

pick-rate

2

per minute

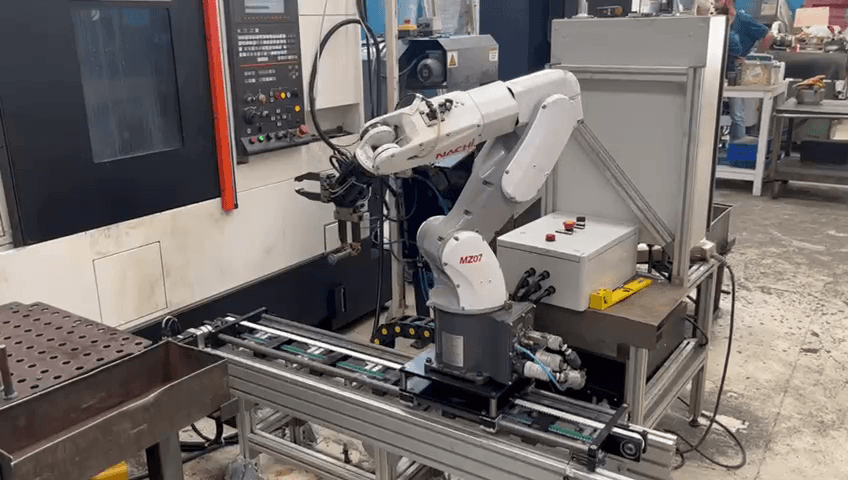

Automating Injection Molding with Robolink: Efficient and Cost-Effective Parts Handling

The plastics industry relies heavily on efficient processes to stay competitive, and automation is becoming a key factor. In this application, the igus Robolink robotic arm automates the handling of ice scraper blanks in an injection molding machine, replacing repetitive manual work. Equipped with a vacuum end effector, the robot picks up blanks, places them in the machine, and removes finished parts. Its 180-degree rotation ensures both loading and unloading occur in a single cycle, significantly improving efficiency.

What is the Application?

The system automates parts handling for injection molding machines. It places blanks into molds, removes finished products, and positions them on a conveyor belt, ensuring smooth workflows.

What are the Advantages of the Solution?

Fast ROI: Affordable costs enable payback within approximately four months.

Increased Productivity: Reduces manual effort to just 10% of shift time.

Ease of Use: Intuitive software eliminates the need for IT experts.

What are the Advantages of the Robot?

The igus Robolink arm delivers reliable performance:

Compact Design: Operates within the machine’s footprint for space efficiency.

Durable Components: Made from lightweight, energy-saving high-performance plastics.

Low Maintenance: Plastic bearings run without lubrication, reducing upkeep costs.

Revolutionizing Plastic Processing with Robolink

The igus Robolink robotic arm exemplifies cost-effective automation in the plastics industry. By reducing labor intensity, improving efficiency, and enabling straightforward operation, it transforms injection molding processes. Combined with platforms like RBTX for seamless system expansion, this solution empowers companies to embrace Industry 4.0 with minimal risk and maximum impact.

4 Components