1 / 3

1 / 3Camera-based pick and place

Hardware Price:

DOF

3

Project costs

12.218,47

€

Repeatability

0.8

mm

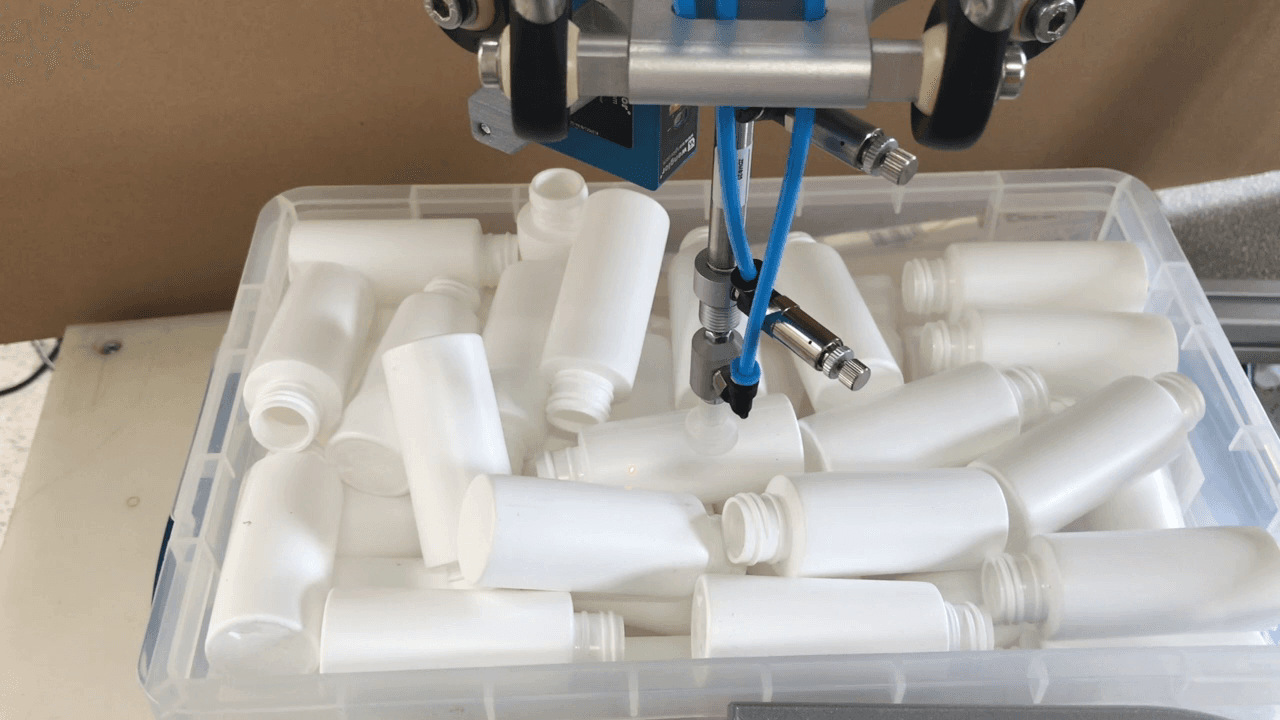

Pick-and-Place Automation with Spatial Gantry and Camera System

Modern manufacturing demands flexibility and efficiency, even in repetitive tasks. This application integrates a spatial gantry system with a camera-based vision system to automate pick-and-place operations. The camera ensures intelligent object recognition, allowing the robot to identify and grip components in varying positions. This flexibility enhances system reliability while optimizing workflows across production lines.

What is the Application?

The solution automates pick-and-place tasks, removing the need for pre-aligned components. Using a camera system, the gantry identifies parts in real-time for precise gripping and placement.

What are the Advantages of the Solution?

Increased Flexibility: Adapts to objects in inconsistent positions.

Lower Costs: Continuous 3-shift operation reduces labor expenses.

Faster ROI: Pays for itself within months due to improved efficiency.

What are the Advantages of the Robot?

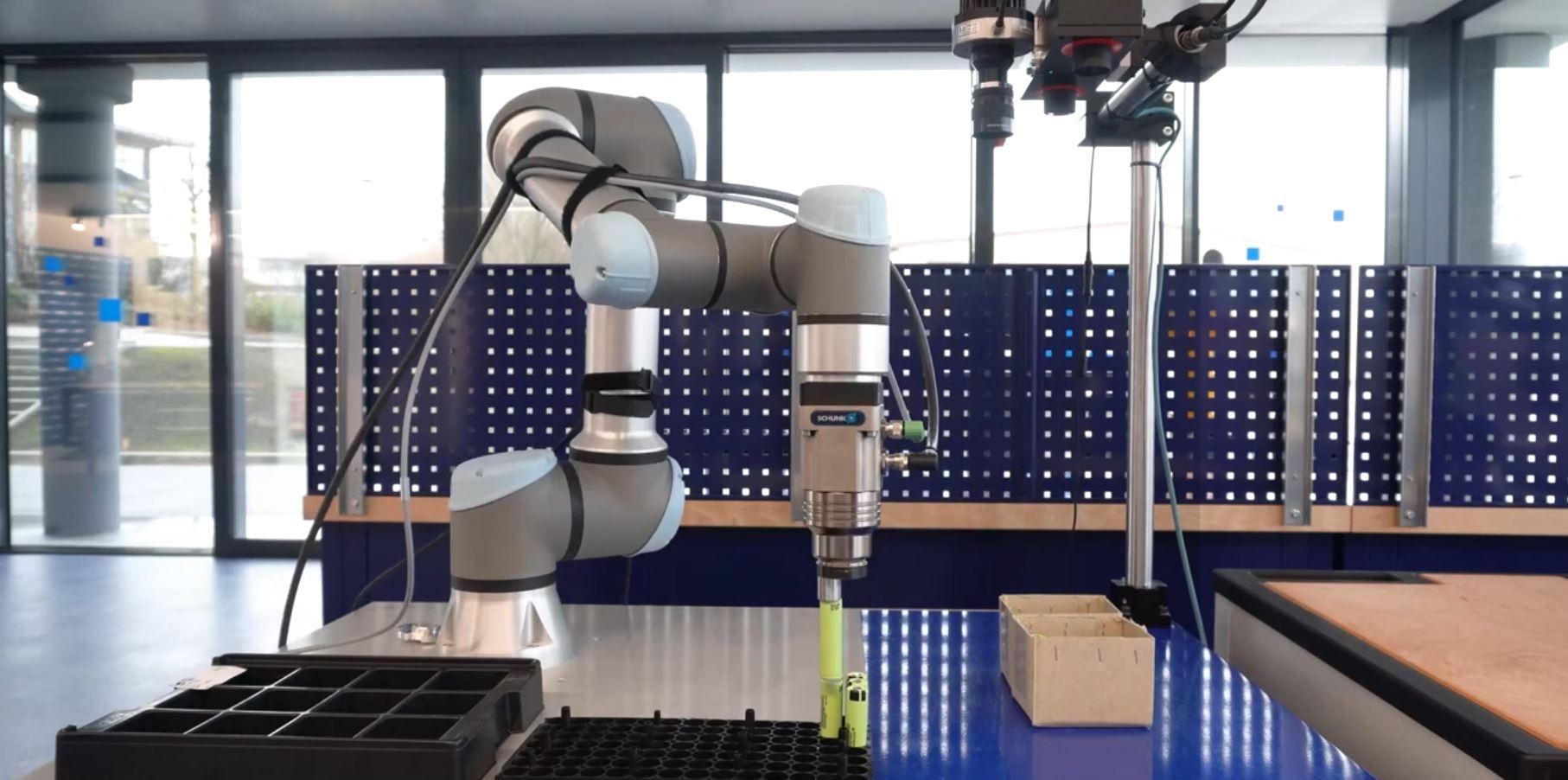

The spatial gantry offers distinct benefits in automated environments:

Precise Movements: Coordinates with the camera for accurate handling.

High Durability: Sustains 24/7 operation with minimal maintenance.

Compact Design: Easily integrates into existing production setups.

Flexible and Cost-Effective Pick-and-Place Automation

This spatial gantry and camera system demonstrates how intelligent automation can reduce costs while enhancing performance. By relieving workers from repetitive tasks and increasing operational flexibility, this solution ensures a rapid return on investment and scalable efficiency for manufacturers.

3 Components